electrical discharge machining working principle

Electrical discharge machiningEDM is used to machine very hard materials. Examples of self-absorption correction a line profiles from plasma.

Electric Discharge Machining Advantages Disadvantages

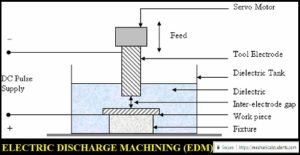

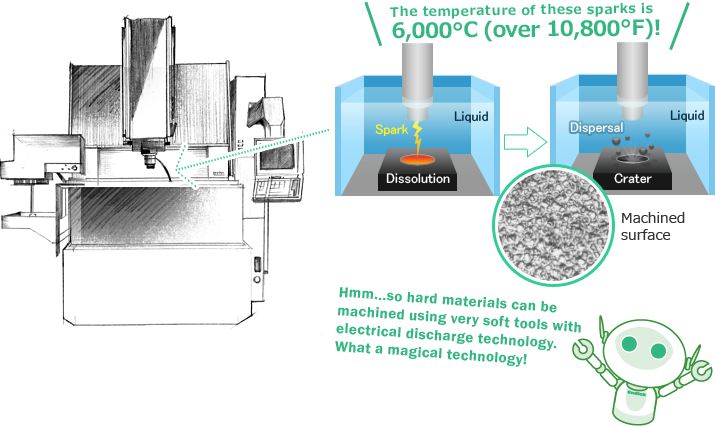

Electrical discharge machining EDM is a process of removing material by exposing it to reoccurring controlled electric discharge.

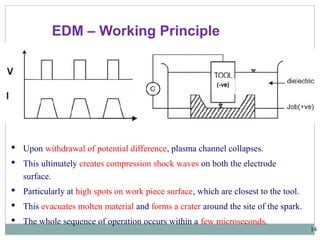

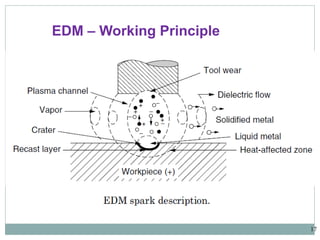

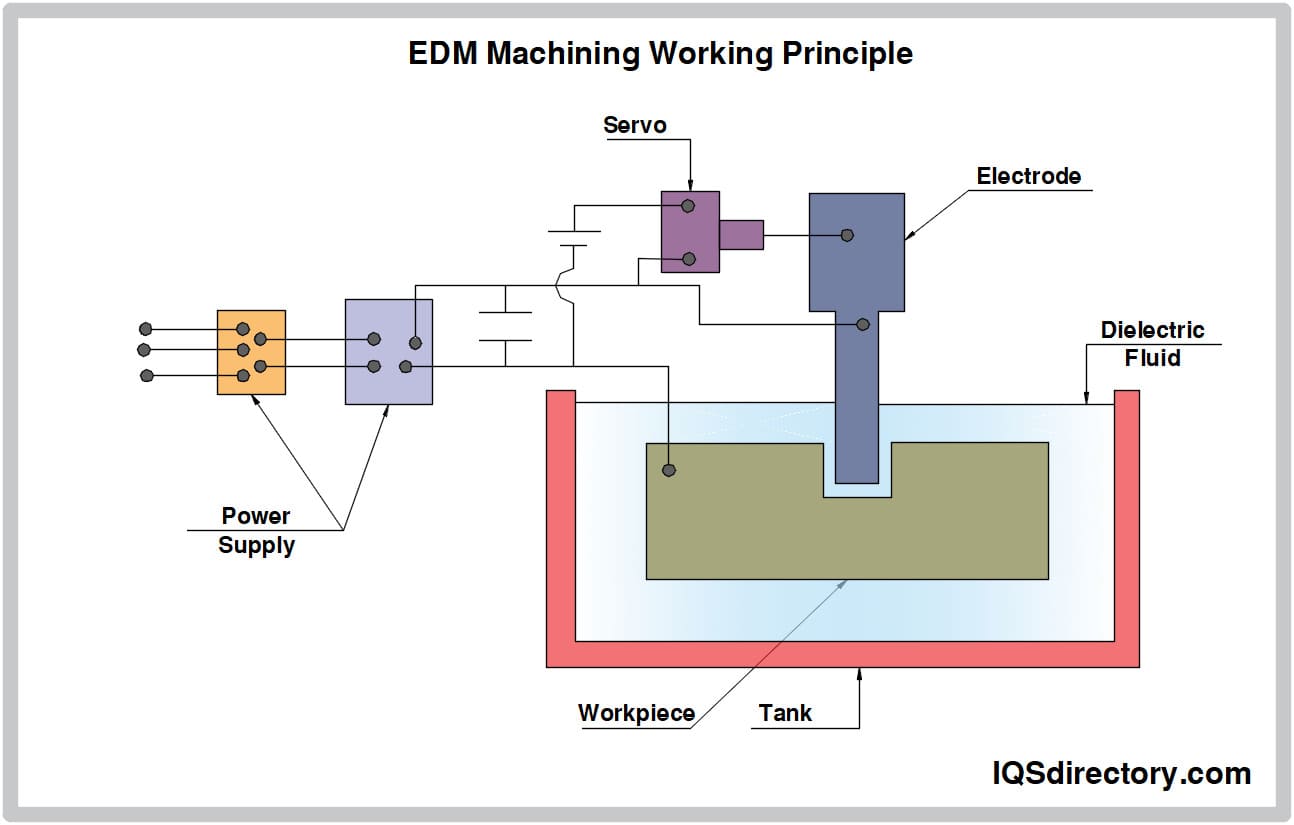

. Working Principle of electrical discharge machining-Here is the working principle of EDM machining EDM. Between the machine tool and the workpiece positive and negative electrodes a method of machining to remove. Electrical discharge machining EDM is a process of removing material by exposing it to repetitive controlled electrical discharges.

The electrical discharge machining working process is based on the generation of sparks and metal removal through spark erosion. Electric discharge machining also known as spark erosion electro-erosion or spark machining is a metal removal process that uses an interrupted electric spark discharge between the. There are several unique advantages associated with EDM manufacturing.

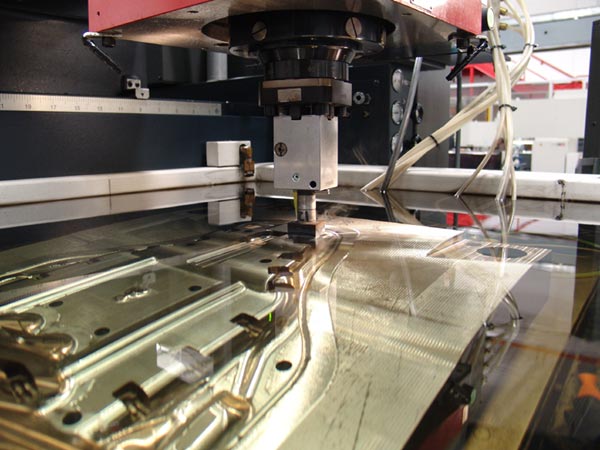

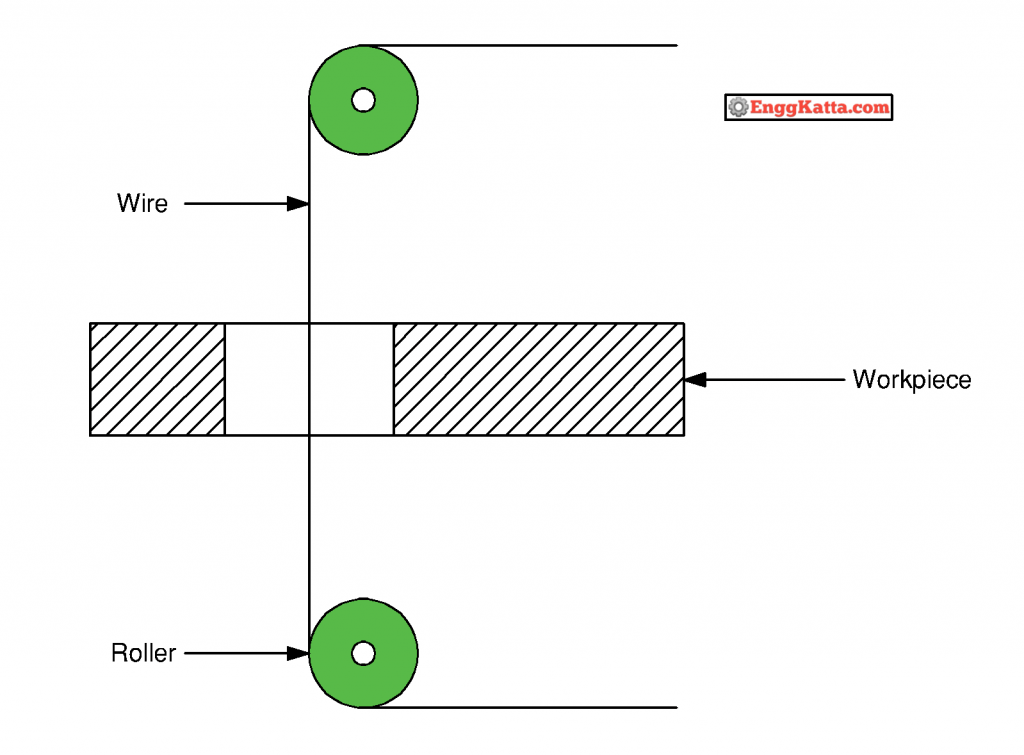

Advantages of Electrical Discharge Machining. The electric discharge machine provides. Explanation about eletrical discharge machining wire cut working principle wire EDM animation and wire EDM application by machining a mouldOther interestin.

Electrical discharge machining EDM is a subtractive manufacturing process converting electrical discharge into thermal energy. Electrical Discharge Machining EDM is a non conventional machining process which can be used to machine electrically conductive work piece. The working principle of electrical discharge machining is.

Electrical discharge Machining Working Principle. You all know about conventional machines like lathe milling grinding or drilling where the cutting tool is always. Explanation of EDMAudio.

16 Pictures about Examples of self-absorption correction a line profiles from plasma. Introduction to Electric Discharge Machining EDM 2. January 6 2021 WMTMETAL 0 Comments Electrical discharge machining EDM is a new technology that uses electric energy and heat energy to process.

Work on Any Type of Electrically. It is suitable for thermoelectric. Mechanics of EDM 3.

It works on the thermo-electrical. Some of them include. In this article we will discuss about the electric discharge machining EDM- 1.

The term EDM stands for Electrical Discharge Machining.

Electrical Discharge Machining Wikipedia

Wire Edm Wire Electro Discharge Machining Engineeringclicks

Mas 865 How To Make Something That Makes Almost Anything

Mechanical Engineering Electrical Discharge Machining Edm Principles

Wire Cut Electrical Discharge Machining Wedm Enggkatta

Electrical Discharge Machining

Electric Discharge Machining English Youtube

Electrical Discharge Machining Edm Process Basics Mechstudies Com

Recently Evaluated Electrical Discharge Machining Edm Process Performances A Research Perspective Sciencedirect

Principles Of Electrical Discharge Machining And Non Consumable Electrode Circuits The Art Of Monodzukuri Techniques For Creating Things Sodick Magazine Sodick

Working Principles Of Electrical Discharge Machining

Electric Discharge Machining Advantages Disadvantages

Electrical Discharge Machining

What Is Wire Edm Electrical Discharge Machining Xact

Electrical Discharge Machining How Edm Machine Works

Edm Machining Components Types Applications And Advantages

Principle And Manufacturing Applications Of Electrical Discharge Machining Edm Part 1